The process of tanning leather is a crucial step in transforming animal hides into durable, long-lasting material that can be used for a variety of products, from clothing and shoes to furniture and accessories. The raw materials used in tanning play a key role in determining the quality and properties of the finished leather. Understanding the various raw materials involved in the tanning process is essential for anyone involved in the leather industry.

One of the main raw materials used in tanning leather is the animal hide itself. The hides are typically obtained from animals such as cattle, sheep, goats, and pigs, which are raised for their meat and other by-products. The quality of the hides is influenced by factors such as the animal's breed, age, and the conditions in which it was raised. Hides with fewer blemishes and a more even thickness are generally preferred for leather production.

In addition to animal hides, tanneries also use a variety of chemicals and natural substances to facilitate the tanning process. One of the most traditional tanning agents is tannin, a naturally occurring polyphenolic compound found in plants such as oak, chestnut, and quebracho. Tannin is known for its ability to bind to the collagen fibers in the animal hide, giving the leather its strength, flexibility, and resistance to decay. Tanneries may obtain tannin by extracting it from raw plant materials or by using commercially available tannin extracts.

Another common tanning agent is chromium salts, which are widely used in modern leather production. Chromium tanning is known for its speed and efficiency, as well as its ability to produce soft, supple leather with excellent color retention. However, the use of chromium in tanning has raised environmental concerns due to the potential for toxic waste and pollution. Tanneries must adhere to strict regulations and best practices to minimize the environmental impact of chromium tanning.

Other chemical substances used in the tanning process include acids, bases, and various synthetic tanning agents. These chemicals help to remove hair and flesh from the hides, adjust the pH of the tanning solution, and facilitate the binding of tannins or chromium to the collagen fibers. Tanneries must handle these chemicals carefully to ensure worker safety and environmental protection.

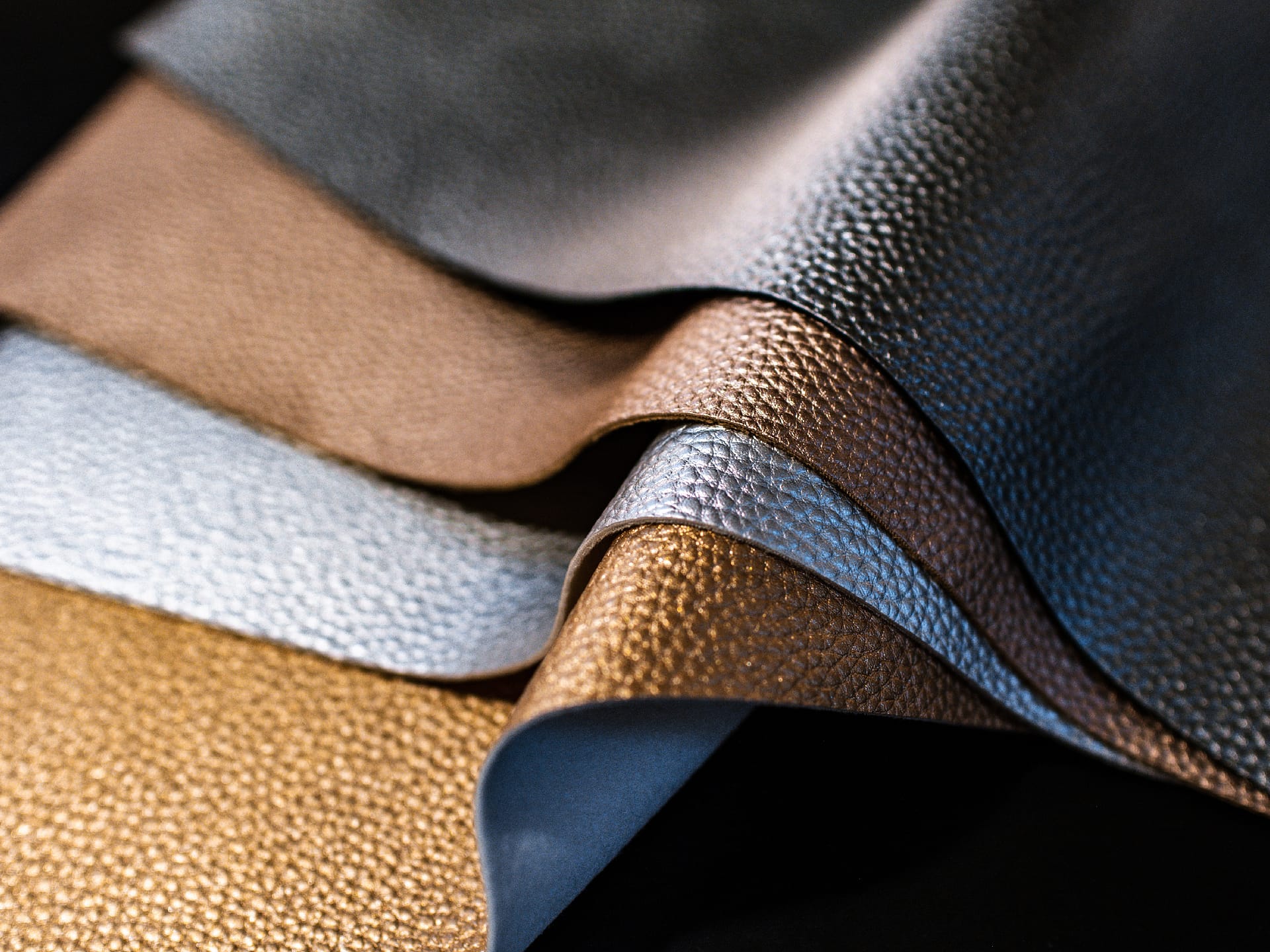

In addition to the main tanning agents, tanneries may use a variety of auxiliary materials to achieve specific properties or finishes in the leather. These may include dyes and pigments for coloration, oils and waxes for softness and water resistance, and finishing agents such as resins and polymers for texture and luster. The choice of auxiliary materials depends on the desired characteristics of the finished leather, whether it be for a high-end fashion item or a rugged outdoor product.

The selection and combination of raw materials for tanning leather is a complex and specialized process that requires a deep understanding of chemistry, biology, and material science. Tanneries must carefully balance factors such as cost, environmental impact, and regulatory compliance while striving to produce high-quality leather that meets the demands of the market.

As consumer awareness of environmental and ethical issues grows, there is increasing interest in sustainable and eco-friendly tanning practices. Some tanneries are exploring alternative tanning agents derived from renewable sources, such as bark and fruit extracts, as well as innovative technologies such as enzymatic and vegetable tanning. These efforts aim to reduce the reliance on chemicals and minimize the ecological footprint of leather production.

Overall, the raw materials for tanning leather are diverse and multifaceted, reflecting the rich history and ongoing innovation in the leather industry. By understanding and carefully managing these raw materials, tanneries can continue to produce high-quality leather that meets the needs of consumers while addressing the challenges of sustainability and environmental stewardship.

Post time: Mar-14-2024