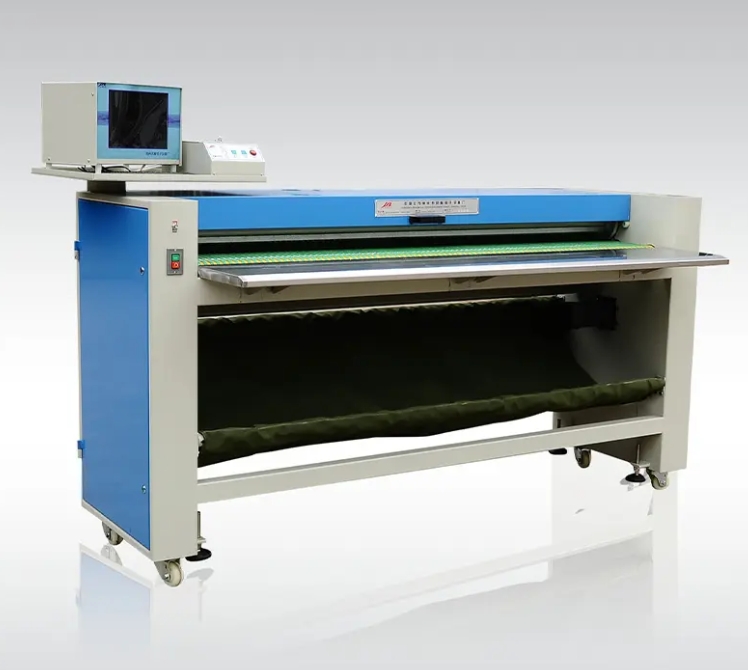

In today's rapidly evolving leather manufacturing sector, where efficiency and digitalization are paramount, a groundbreaking Automatic Leather Measuring Machine has been launched, offering unprecedented intelligent solutions for leather processors. Combining high-precision measurement, smart sorting, and multilingual printing capabilities, this advanced equipment significantly enhances measurement accuracy and operational efficiency through cutting-edge control technology and high-speed CNC motors.

Key Technological Advantages: Precision, Efficiency & Intelligence

1. Stable and Reliable Measurement System

Incorporates the latest control technology to ensure consistent, error-free measurements across various leather types (cowhide, sheepskin, synthetic leather, etc.).

Built with a rugged structure for continuous heavy-duty operation in demanding production environments.

2. Dual-Size Simultaneous Printing for Enhanced Productivity

Prints both standard size (Normal Size) and box dimensions (Box Size) concurrently, meeting diverse customization needs.

High-definition printing with adjustable formats ensures long-lasting, fade-resistant markings.

3. Intelligent Leather Sorting for Quality Control

Features Leather Choose Function to automatically detect defects (uneven thickness, damage, etc.), excluding substandard leather from final calculations.

Reduces material waste and improves utilization of premium-grade leather.

4. Bilingual Operation for Global Compatibility

Supports Chinese and English input via PC keyboard, allowing flexible printing in either or both languages—ideal for export-oriented businesses.

Generates digital measurement reports for easy archiving and management.

5. Expandable Functionality for Smart Manufacturing

Optional add-ons include Label Printer and Barcode Printer for efficient leather classification.

PC connectivity enables real-time data transfer to ERP/MES systems, facilitating Industry 4.0 integration.

6. High-Speed Automated Printing (GLGWQ Model Only)

Powered by high-speed CNC motors for rapid, precise marking—ideal for mass production.

Boosts productivity by over 50% by minimizing manual intervention.

Industry Applications: Optimizing Leather Production

Leather Traders: Quickly measures and documents hide dimensions, generating standardized reports to enhance transaction transparency.

Furniture & Automotive Interiors Suppliers: Accurately calculates leather yield to optimize cutting plans and reduce costs.

Footwear & Luggage Manufacturers: Enables production traceability via barcode systems while improving quality control.

Market Outlook: A New Benchmark for Smart Manufacturing

As global demand grows for automated, data-driven solutions, traditional manual measurement methods are becoming obsolete. This intelligent measuring machine—with its unmatched accuracy, smart filtering, and cloud compatibility—is poised to become the industry norm. Already gaining traction in key leather-producing nations like China, Vietnam, and Italy, it represents the future of efficient leather processing.

The Future Is Here

By eliminating the inefficiencies and inaccuracies of conventional measurement, this fully automated, scalable solution ushers leather manufacturing into the era of precision measurement and digital management. It’s not just a machine—it’s a transformative tool empowering manufacturers worldwide to achieve smarter, faster, and more reliable production.

Post time: May-15-2025