Manufacturer for Leather Machine To Process Raw Hides - Hang Conveyor Dry Leather Machine For Cow Sheep Goat Leather – SHIBIAO

Manufacturer for Leather Machine To Process Raw Hides - Hang Conveyor Dry Leather Machine For Cow Sheep Goat Leather – SHIBIAO Detail:

Product Video

A Hang Conveyor

1. This machine install on the top of the workshop, it is nature dry use the workshop air and hot.

2. This machine possible install on the top of the building.

3. Worker just for loading and unloading the skin.

4. Consisted of runway, conveyor, hanger and drive system.

5. Optional to install the hang dryer oven for dry fast.

6. “H” style hanger with clips or “U” style hanger.

|

Technical Parameters |

|||

|

Model |

GGZX406 |

||

|

Conveyor speed (m/min) |

0.3-7 |

Distance between hanger (mm) |

406 |

|

Point loading weight (kg) |

30-50 |

Power (kW) |

1.1-1.5 |

|

Dry number (pc/m) |

5-10 |

Turn Round Diameter (m) |

≥0.8 |

|

Note: The length and width can be customized size |

|||

Product Details

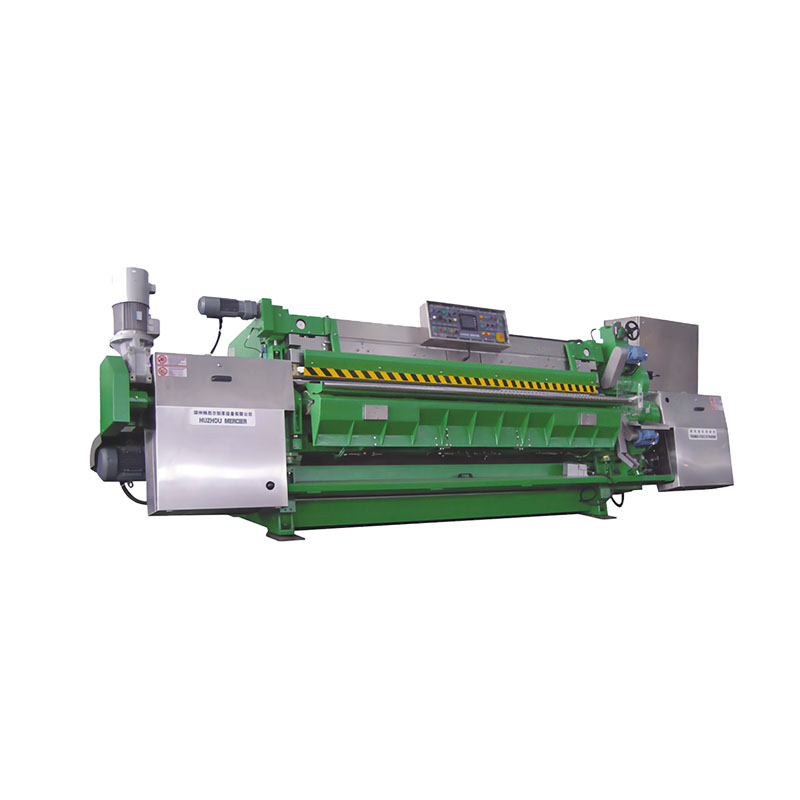

B Double Layer Rotary Dryer (Pole Dryer)

1.Consisted of two layers. Feeding leather skins from the lower layer and out of skin from the upper layer.

2. The drying channel is sheared and welded by plate and section bar, to form a complete channel. Use double-sided color steel sandwich plate to form a whole sealing frame, achieving a good thermal insulation properties of drying channel.

3. The conveyor is consisted of drive unit, pathway, chain and hangers.

4. Steam heating source .Heating unit is consisted of radiator, axial flow fan, to form a complete hot air circulation device. Every two meter form a unit, every unit has two hearing units.

5. Moisture removing unit: provides two centrifugal fan on the bottom to remove moisture in the channel.

6. Auto control the temperature and humidity.

|

Technical Parameters |

|||

|

Model |

GGZD4 300/6-300/14 |

||

|

Working width(mm) |

3000 |

Steam kg/h |

160-640 |

|

Conveyor speed (m/min) |

1.1-4.4 |

Hangers (pc) |

151-308 |

|

Working temperature(℃) |

20-70 |

Power (kW) |

14.32-37.92 |

|

Capacity (pc/h) |

480-960 for sheep skin |

320-640 for pig skin |

160-320 for cattle skin |

|

Note: The length and width can be customized size |

|||

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff and also the consistent purpose of reputation very first, shopper first for Manufacturer for Leather Machine To Process Raw Hides - Hang Conveyor Dry Leather Machine For Cow Sheep Goat Leather – SHIBIAO , The product will supply to all over the world, such as: Jamaica, Birmingham, Dubai, Now we are sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We are ready to share win-win corporation.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!