Good Quality Oil Tanning Leather Process - Hang Conveyor Dry Leather Machine For Cow Sheep Goat Leather – SHIBIAO

Good Quality Oil Tanning Leather Process - Hang Conveyor Dry Leather Machine For Cow Sheep Goat Leather – SHIBIAO Detail:

Product Video

A Hang Conveyor

1. This machine install on the top of the workshop, it is nature dry use the workshop air and hot.

2. This machine possible install on the top of the building.

3. Worker just for loading and unloading the skin.

4. Consisted of runway, conveyor, hanger and drive system.

5. Optional to install the hang dryer oven for dry fast.

6. “H” style hanger with clips or “U” style hanger.

|

Technical Parameters |

|||

|

Model |

GGZX406 |

||

|

Conveyor speed (m/min) |

0.3-7 |

Distance between hanger (mm) |

406 |

|

Point loading weight (kg) |

30-50 |

Power (kW) |

1.1-1.5 |

|

Dry number (pc/m) |

5-10 |

Turn Round Diameter (m) |

≥0.8 |

|

Note: The length and width can be customized size |

|||

Product Details

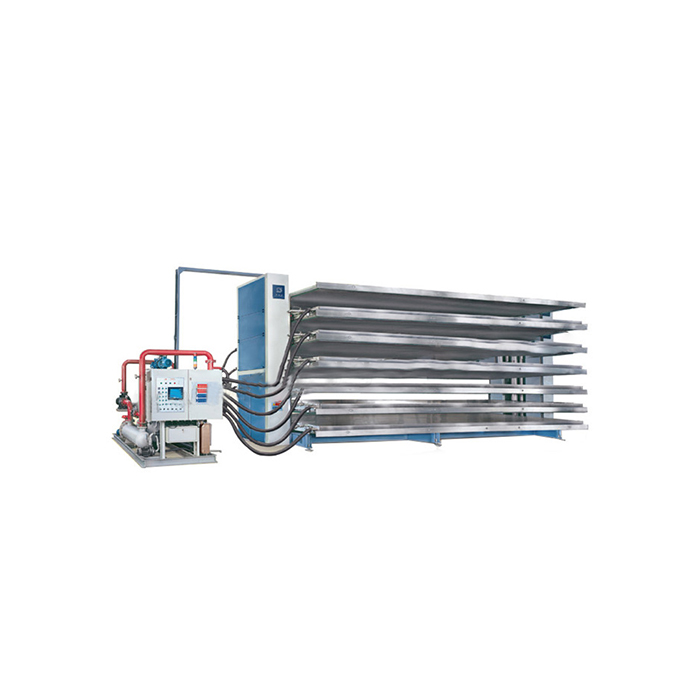

B Double Layer Rotary Dryer (Pole Dryer)

1.Consisted of two layers. Feeding leather skins from the lower layer and out of skin from the upper layer.

2. The drying channel is sheared and welded by plate and section bar, to form a complete channel. Use double-sided color steel sandwich plate to form a whole sealing frame, achieving a good thermal insulation properties of drying channel.

3. The conveyor is consisted of drive unit, pathway, chain and hangers.

4. Steam heating source .Heating unit is consisted of radiator, axial flow fan, to form a complete hot air circulation device. Every two meter form a unit, every unit has two hearing units.

5. Moisture removing unit: provides two centrifugal fan on the bottom to remove moisture in the channel.

6. Auto control the temperature and humidity.

|

Technical Parameters |

|||

|

Model |

GGZD4 300/6-300/14 |

||

|

Working width(mm) |

3000 |

Steam kg/h |

160-640 |

|

Conveyor speed (m/min) |

1.1-4.4 |

Hangers (pc) |

151-308 |

|

Working temperature(℃) |

20-70 |

Power (kW) |

14.32-37.92 |

|

Capacity (pc/h) |

480-960 for sheep skin |

320-640 for pig skin |

160-320 for cattle skin |

|

Note: The length and width can be customized size |

|||

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for Good Quality Oil Tanning Leather Process - Hang Conveyor Dry Leather Machine For Cow Sheep Goat Leather – SHIBIAO , The product will supply to all over the world, such as: The Swiss, French, Ecuador, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.