Factory Supply Through-Feed Samming Machine - Shaving Machine Tannery Machine For Cow Sheep Goat Leather – SHIBIAO

Factory Supply Through-Feed Samming Machine - Shaving Machine Tannery Machine For Cow Sheep Goat Leather – SHIBIAO Detail:

Product Video

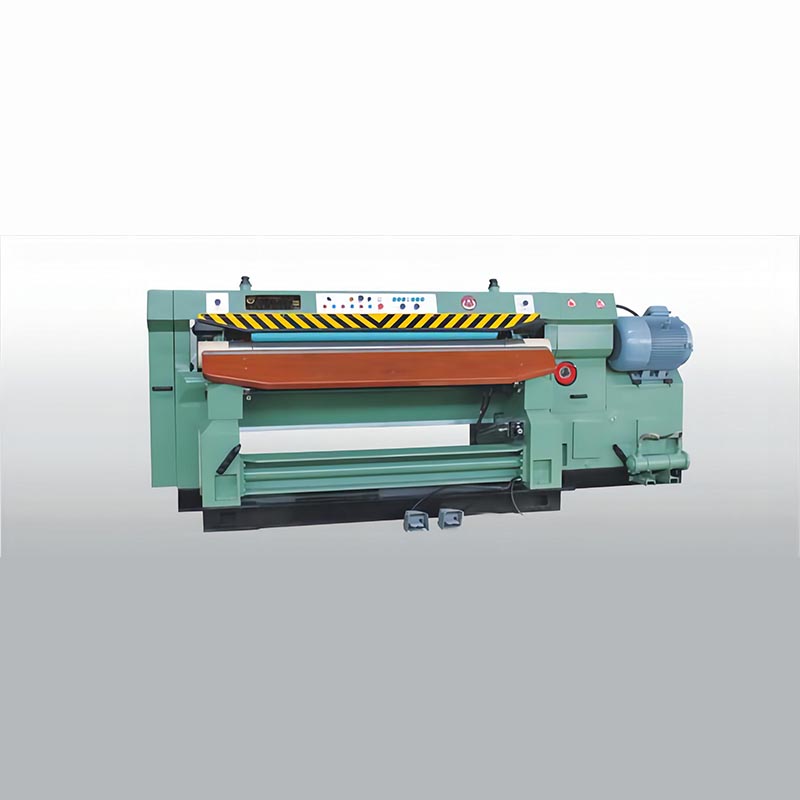

A Wet Shaving Machine

1. Driving way combined hydraulic and mechanical transmission way.

2. Blade roller driven by motor directly, has been balance and rectified, running stably.

3. Feeding roller adopts hydraulic variable speed ,1-25m/min.

4. Grinding blade driven by motor through gear box, three kinds of grinding way.

5. Manual/Auto way to adjust shaving thickness.

6. Through shaving, leather thickness is uniform, leather back side is clean and smooth.

|

Technical Parameter |

||||||||

|

Model |

Working width (mm) |

Feeding speed (m/min) |

Mini shaving thickness(mm) |

Shaving uniformity(%) |

Production pc/h |

Total power (kW) |

Dimension(mm) L×W×H |

Weight (kg) |

|

GXYY-150B |

1500 |

1-25 |

0.5 |

±15 |

70-100 |

42.8 |

3970×1540×1670 |

6100 |

|

GXYY-180B |

1800 |

1-25 |

0.5 |

±15 |

70-100 |

42.8 |

4270×1540×1670 |

6500 |

|

GXYY-300A |

3000 |

1-25 |

0.8 |

±15 |

40-50 |

89 |

6970×1810×1775 |

14500 |

Product Details

B Wet Shaving Machine For Small Skins

For shaving wet blue leather of sheep & goat.

|

Technical Parameter |

|||||||

|

Model |

Working width (mm) |

Feeding speed (m/min) |

Mini shaving thickness(mm) |

Total power (kW) |

Drive way |

Dimension(mm) L×W×H |

Weight (kg) |

|

GXY-45C |

450 |

7.4-11.7 |

0.4 |

8.6 |

Mechanical |

2100×1276×1454 |

2200 |

|

GXY-1080 |

1080 |

8-30 |

0.6 |

22.62 |

Hydraulic |

2250×1950×1600 |

4100 |

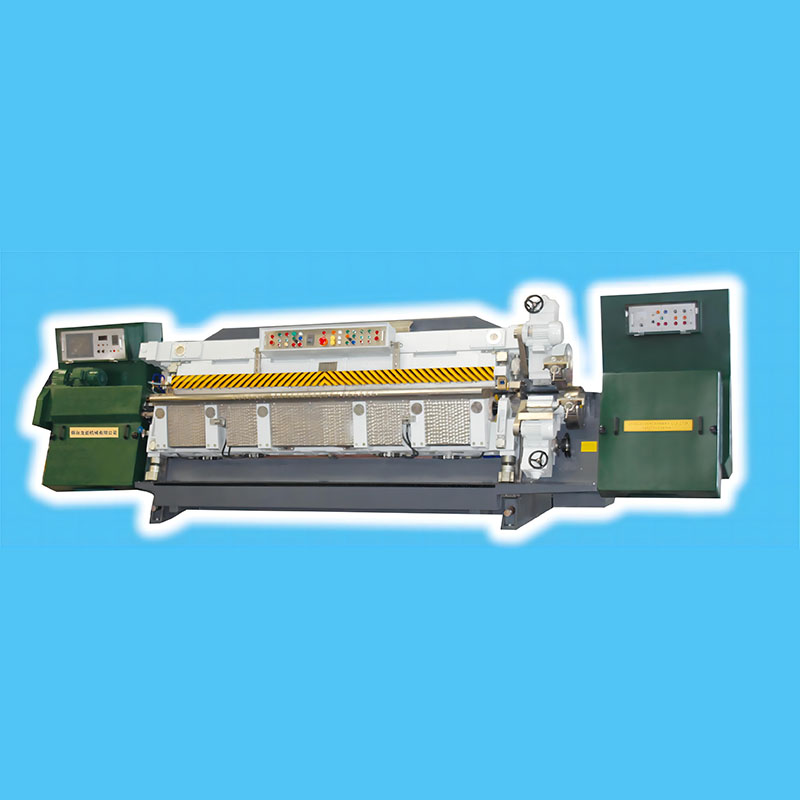

C Dry Shaving Machine

For shaving dry leather of cattle, cow, pig and sheep, goat.

1. Strong structure made in cast iron.

2. Hydraulic opening and closing.

3. Feeding roller driven by hydraulic motor.

4. Controlled by PLC, with touch screen.

5. Three sharpening ways: occasional, periodic and continuous.

6. Grinder carriage driven by inverter, variable speed.

7. Grinding wheel backs off from blade cylinder when machine stops.

8. Automatically recovery of blade wear.

9. Thickness increasing and decreasing device.

10. Top and bottom dust collecting devices for the dry shaving (optional).

| Technical Parameter | |||||

|

Model |

Working width (mm) |

Feeding speed (m/min) |

Total power (kW) |

Dimension(mm) L×W×H |

Weight (kg) |

|

SW12 |

1200 |

1-30 |

44.1 |

3790×1930×1700 |

5700 |

|

SW15 |

1500 |

1-30 |

44.1 |

4090×1930×1700 |

6100 |

|

SW18 |

1800 |

1-30 |

44.1 |

4390×1930×1700 |

6500 |

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Factory Supply Through-Feed Samming Machine - Shaving Machine Tannery Machine For Cow Sheep Goat Leather – SHIBIAO , The product will supply to all over the world, such as: Rio de Janeiro, Zimbabwe, El Salvador, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!